Features

•Heavy one-piece steel frame, minimizing deflection, high accuracy.

•Pneumatic wet clutch brake,longer service life.

•8-points slide guiding, stronger stability and resistance to eccentric-load. Adopting Quenching & Grinding Process for Slide-Guide,which can make the press machine higher accuracy & low wear and provide increased tool life.

•Forged 42CrMo alloy material crankshaft, its strength is 1.3 times higher than that of #45 steel, and service life is longer.

•Copper sleeve is made of tin phosphorus bronze ZQSn10-1, which has a strength 1.5 times higher than that of ordinary BC6 brass.

•Highly sensitive hydraulic overload protection device,effectively protect the service life of the presses and tools.

•Forced thin re-circulating oil lubrication device, energy-saving, environmentally friendly, equipped with automatic alarm function, with better smoothness and heat dissipation, and better lubrication effect.

•Built to JIS Class I accuracy standard.

•Optional Die Cushion.

Specifications

Technical parameter

| Specifications | Unit | STD-160 | STD-200 | STD-250 | |||

| Mode | S-type | H-type | S-type | H-type | S-type | H-type | |

| Press capacity | Ton | 160 | 200 | 250 | |||

| Rated tonnage point | mm | 6 | 3 | 6 | 3 | 7 | 3.5 |

| Slide strokes per minute | S.P.M | 20~50 | 40~70 | 25~50 | 40~80 | 20~45 | 30~60 |

| Slide stroke length | mm | 200 | 90 | 200 | 100 | 250 | 150 |

| Max die height | mm | 450 | 400 | 450 | 400 | 450 | 400 |

| Slide adjustment amount | mm | 100 | 120 | 120 | |||

| Slide Area | mm | 750*700 | 800*800 | 1000*900 | |||

| Bolster Area | mm | 950*800 | 1000*900 | 1200*1000 | |||

| Side opening | mm | 700*500 | 700*500 | 700*600 | |||

| Main motor power | KW*P | 15*4 | 18.5*4 | 22*4 | |||

| Air pressure | kg*cm² | 6 | 6 | 6 | |||

| Press accuracy grade | Grade | JIS 1 | JIS 1 | JIS 1 | |||

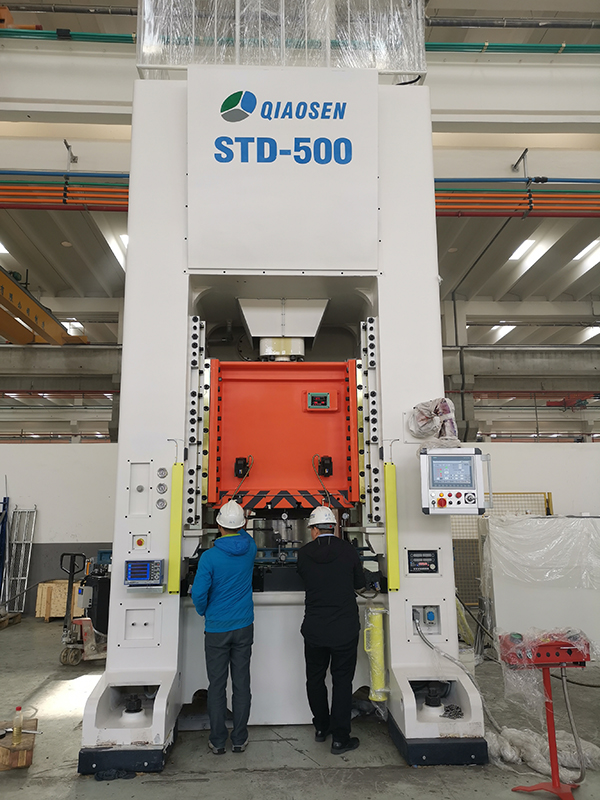

| Specifications | Unit | STD-300 | STD-400 | STD-500 | STD-630 | ||||

| Mode | S-type | H-type | S-type | H-type | S-type | H-type | S-type | H-type | |

| Press capacity | Ton | 300 | 400 | 500 | 630 | ||||

| Rated tonnage point | mm | 7 | 3.5 | 8 | 4 | 10 | 5 | 10 | 5 |

| Slide strokes per minute | S.P.M | 20~40 | 30~60 | 20~40 | 30~60 | 20~40 | 30~60 | 20~40 | 30~60 |

| Slide stroke length | mm | 300 | 150 | 300 | 150 | 300 | 150 | 300 | 150 |

| Max die height | mm | 550 | 450 | 550 | 450 | 600 | 650 | 650 | 550 |

| Slide adjustment amount | mm | 150 | 150 | 150 | 150 | ||||

| Slide Area | mm | 1100*1000 | 1200*1000 | 1300*1200 | 1400*1200 | ||||

| Bolster Area | mm | 1300*1100 | 1400*1100 | 1500*1300 | 1600*1300 | ||||

| Side opening | mm | 700*600 | 900*650 | 900*700 | 900*700 | ||||

| Main motor power | KW*P | 30*4 | 37*4 | 45*4 | 55*4 | ||||

| Air pressure | kg*cm² | 6 | 6 | 6 | 6 | ||||

| Press accuracy grade | Grade | JIS 1 | JIS 1 | JIS 1 | JIS 1 | ||||

| Our company is ready to carry out research and improvement work at any time. Therefore, the size design characteristics specified in this catalogue can be changed without further notice. | |||||||||

Standard Configuration

| > | Hydraulic overload protection device | > | Air blowing device |

| > | Electric slider adjusting device | > | Mechanical shockproof feet |

| > | Variable frequency variable speed motor (adjustable speed) | > | Mis-feeding detection device reserved interface |

| > | Electronic cam device | > | Maintenance tools and toolbox |

| > | Digital die height indicator | > | Main motor reversing device |

| > | Slider and stamping tools balance device | > | Light Curtain (Safety Guarding) |

| > | Rotating cam controller | > | Wet Clutch |

| > | Crankshaft angle indicator | > | Electric grease lubrication device |

| > | Electromagnetic counter | > | Touch screen (pre-break, pre-load) |

| > | Air source connector | > | Mobile electric control cabinet and console |

| > | Second degree falling protecting device | > | LED die lighting |

| > | Forced Thin Re-Circulating Oil Lubrication System Device | > | 8-Points Slide Guiding |

Optional Configuration

| > | Customization Per Customer Requirement | > | Foot Switch |

| > | Die Cushion | > | Electric Automatic Grease Lubrication Device |

| > | Quick Die Change System | > | Dry Clutch |

| > | Slide Knock Out Device | > | Anti-Vibration Isolator |

| > | Turnkey System with Coil Feedline and Automation System | > | Tonnage Monitor |

•Heavy one-piece steel frame, minimizing deflection, high accuracy.

•Pneumatic wet clutch brake,longer service life.

•8-points slide guiding, stronger stability and resistance to eccentric-load. Adopting Quenching & Grinding Process for Slide-Guide,which can make the press machine higher accuracy & low wear and provide increased tool life.

•Forged 42CrMo alloy material crankshaft, its strength is 1.3 times higher than that of #45 steel, and service life is longer.

•Copper sleeve is made of tin phosphorus bronze ZQSn10-1, which has a strength 1.5 times higher than that of ordinary BC6 brass.

•Highly sensitive hydraulic overload protection device,effectively protect the service life of the presses and tools.

•Forced thin re-circulating oil lubrication device, energy-saving, environmentally friendly, equipped with automatic alarm function, with better smoothness and heat dissipation, and better lubrication effect.

•Built to JIS Class I accuracy standard.

•Optional Die Cushion.

Standard Confirguration

| > | Hydraulic overload protection device | > | Air blowing device |

| > | Electric slider adjusting device | > | Mechanical shockproof feet |

| > | Variable frequency variable speed motor (adjustable speed) | > | Mis-feeding detection device reserved interface |

| > | Electronic cam device | > | Maintenance tools and toolbox |

| > | Digital die height indicator | > | Main motor reversing device |

| > | Slider and stamping tools balance device | > | Light Curtain (Safety Guarding) |

| > | Rotating cam controller | > | Wet Clutch |

| > | Crankshaft angle indicator | > | Electric grease lubrication device |

| > | Electromagnetic counter | > | Touch screen (pre-break, pre-load) |

| > | Air source connector | > | Mobile electric control cabinet and console |

| > | Second degree falling protecting device | > | LED die lighting |

| > | Forced Thin Re-Circulating Oil Lubrication System Device | > | 8-Points Slide Guiding |

Optional Configuration

| > | Customization Per Customer Requirement | > | Foot Switch |

| > | Die Cushion | > | Electric Automatic Grease Lubrication Device |

| > | Quick Die Change System | > | Dry Clutch |

| > | Slide Knock Out Device | > | Anti-Vibration Isolator |

| > | Turnkey System with Coil Feedline and Automation System | > | Tonnage Monitor |