Product Introduction

QIAOSEN Servo press machine,the best choice for forming,blanking,drawing,cutting and punching of automotive parts(sheet metal parts stamping forming), which comply and satisfy the trend and application of steel parts with light weight but high tensile strength in automotive industry.

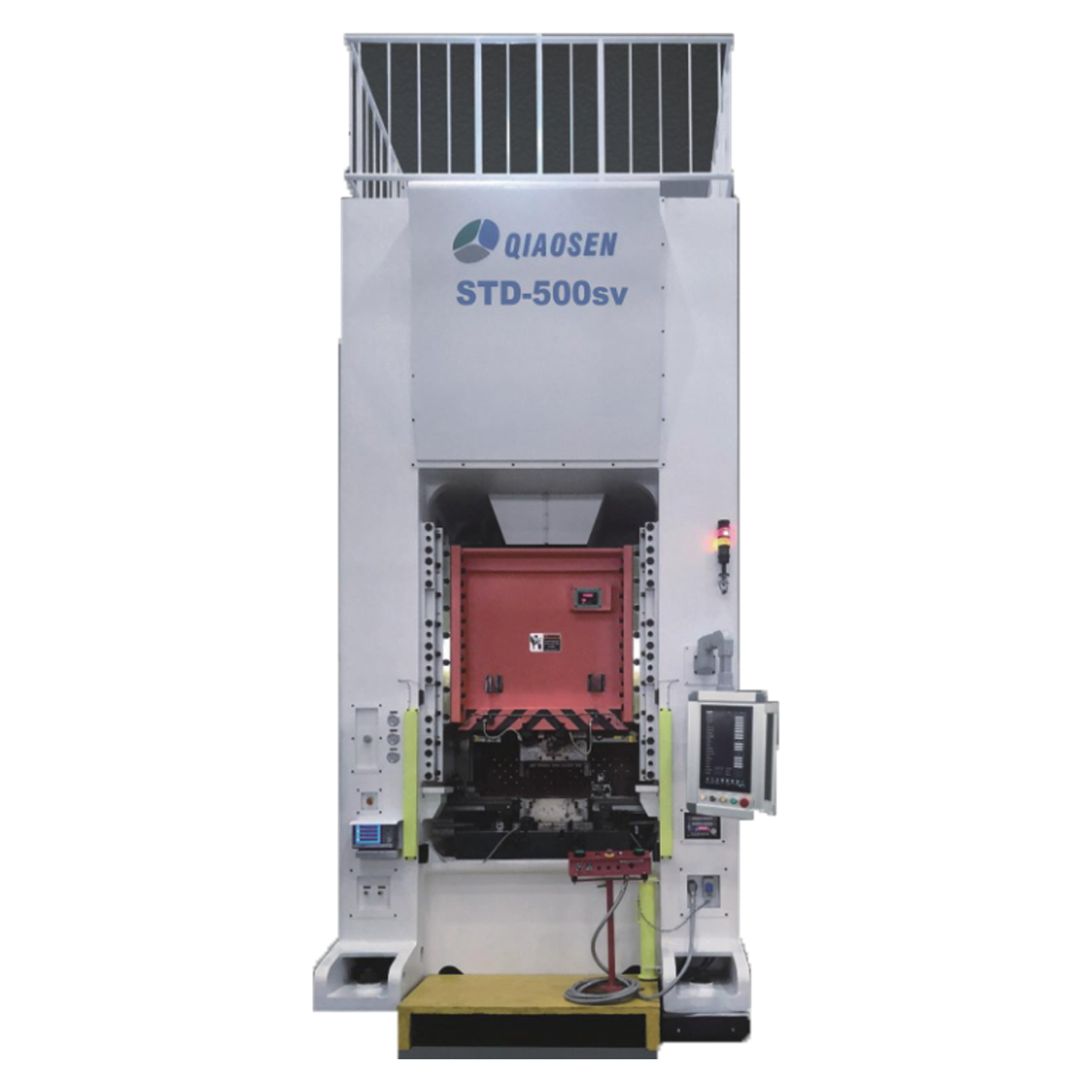

STD Series servo presses are straight side single point servo press machine, which are equipped with powerful direct drive transmission. Suitable for high tensile strength steel product forming and stamping.

Built in with 9 motion curve processing modes in touch screen, the presses system can be programmed according to the processing technology of different products to achieve more motion curves.

Crank presses type design, forged 42CrMo alloy material crankshaft, by combining progressive die with pendulum curve, the productivity can possibly be doubled, which can saving energy and environmental friendly.

Specifications

Technical parameter

| Specifications | Unit | STD-110sv | STD-160sv | STD-200sv | STD-250sv | STD-300sv | STD-400sv | STD-500sv | STD-600sv | STD-800sv |

| Press capacity | Ton | 110 | 160 | 200 | 250 | 300 | 400 | 500 | 600 | 800 |

| Rated tonnage point | mm | 5 | 5 | 5 | 6 | 6 | 6 | 7 | 8 | 9 |

| Slider strokes per minute(S.P.M) (Swing mode) |

mm | ~100 | ~100 | ~100 | ~75 | ~70 | ~70 | ~70 | ~70 | ~60 |

| Slider strokes per minute(S.P.M) (Full stroke) |

mm | ~60 | ~60 | ~60 | ~50 | ~40 | ~40 | ~40 | ~40 | ~35 |

| Max die height | mm | 450 | 450 | 450 | 500 | 550 | 600 | 650 | 650 | 650 |

| Slider adjustment amount | mm | 100 | 100 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| Slide size | mm | 750*700 | 750*700 | 700*700 | 800*800 | 900*900 | 1000*1000 | 1200*1200 | 1300*1300 | 1400*1400 |

| Bolster platform size | mm | 750*800 | 850*800 | 900*900 | 1000*1000 | 1100*1100 | 1200*1200 | 1400*1200 | 1500*1300 | 1600*1400 |

| Side opening | mm | 700*500 | 700*500 | 700*500 | 700*600 | 700*600 | 900*650 | 900*650 | 900*700 | 900*700 |

| Servo motor torque | Nm | 4500 | 7500 | 12000 | 15000 | 21000 | 28000 | 37000 | 46000 | 65000 |

| Air pressure | kg*cm² | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Press accuracy grade | Grade | JIS 1 | JIS 1 | JIS 1 | JIS 1 | JIS 1 | JIS 1 | JIS 1 | JIS 1 | JIS 1 |

| NOTE:Our company is ready to carry out research and improvement work at any time. Therefore, the size design characteristics specified in this catalogue can be changed without further notice. | ||||||||||

Company Profile

QIASEN PRESSES product line covers more than 100 types of presses and services, such as C Frame Single or Double Crank Press Machine, H Frame Single and Double Crank Mechanical Press Machine, Servo Press Machine, Toggle Joint Precision Power Presses, High Speed Press Machine, Presses Servo Feeder Machine.

● Heavy one-piece steel frame, minimizing deflection, high accuracy.

● High strength body structure, small deformation and high precision

● 8-points slide guiding, and the sliding block guide rail adopts “high-frequency quenching” and “rail grinding process”: low wear, high precision, long precision holding time, and improves the service life of the mold.

● The crankshaft is made of high-strength alloy material 42CrMo. Its strength is 1.3 times that of 45 steel and its service life is longer.

● The copper sleeve is made of tin phosphor bronze ZQSn10-1, and its strength is 1.5 times that of ordinary BC6 brass.

● The use of highly sensitive hydraulic overload protection device can effectively protect the service life of the presses and die.

● Forced thin re-circulating oil lubrication device, energy-saving, environmentally friendly, equipped with automatic alarm function, with better smoothness and heat dissipation, and better lubrication effect.

● The standard configuration is high-precision bearing and Japanese NOK seal.

● 15.6 inch touch screen

● Optional Die Cushion.

● 9 processing modes are built-in, and each product can select the processing curve most suitable for component processing, So as to achieve high precision, high efficiency and high energy conservation.

● Compared with traditional presses, it has simple structure, high mechanical transmission efficiency and low maintenance cost.

● According to the characteristics of products/materials, the stamping forming speed can be reduced during the material processing to achieve the best forming speed of products/materials. Thus reducing vibration and stamping noise; Improve product accuracy and extend the service life of the mold.

● According to different products, different heights are required. The stroke of the punch can be set arbitrarily, which greatly shortens the stamping time and improves the efficient.

Standard Confirguration

| > | Hydraulic overload protection device | > | Air blowing device |

| > | Servo Motor(Speed Adjustable) | > | Mechanical shockproof feet |

| > | Electric slider adjusting device | > | Mis-feeding detection device reserved interface |

| > | Independent control cabinet | > | Maintenance tools and toolbox |

| > | Prejudging counter | > | Main motor reversing device |

| > | Digital die height indicator | > | Light Curtain (Safety Guarding) |

| > | Slider and stamping tools balance device | > | Power outlet |

| > | Rotating cam controller | > | Re-Circulating Oil lubrication |

| > | Crankshaft angle indicator | > | Touch screen (pre-break, pre-load) |

| > | Electromagnetic counter | > | Movable two-handed operating console |

| > | Air source connector | > | LED die lighting |

| > | Second degree falling protecting device | Air cooled chiller |

Optional Configuration

| > | Customization Per Customer Requirement | > | Safety Die Door |

| > | Die Cushion | > | Electric grease lubrication device |

| > | Turnkey System with Coil Feedline and Automation System | > | Anti-Vibration Isolator |

| > | Quick Die Change System | > | Tonnage Monitor |

| > | Slide knock out device | > |