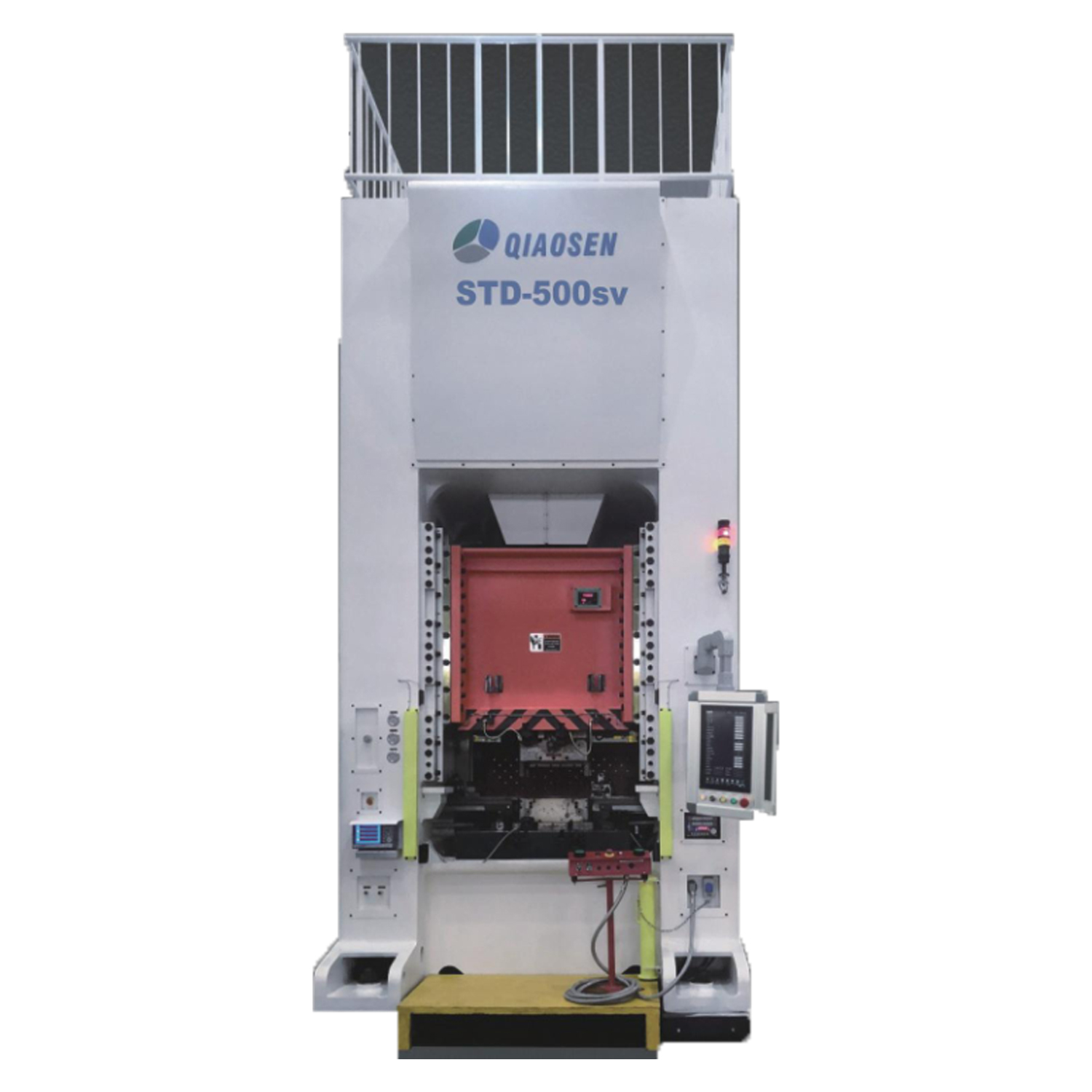

Servo presses, commonly found in industrial settings, play a crucial role in the manufacturing process by providing accurate and repeatable movements. However, to ensure their reliable performance and prevent any unexpected downtime, daily maintenance is essential. Here, we will explore the various tasks involved in the daily maintenance of servo presses.

Visual Inspection

The first step in the daily maintenance of servo presses is visual inspection. This involves carefully inspecting the press for any signs of damage or wear and tear. Components such as the servo motor, reducer, and linkage system should be checked for any abnormalities. Additionally, the lubrication system, including the grease lubrication points, should be inspected to ensure sufficient lubrication.

Checking the Servo System

The servo system is the heart of a servo press, and it requires daily inspection to ensure its proper function. The servo drive and control board should be checked for any damage or foreign objects that may have lodged between the components. Additionally, the connection between the servo drive and motor should be tightened to avoid any loose connections that may affect the performance of the servo press.

Lubrication Check

Proper lubrication is essential to maintain the smoothness and efficiency of servo press operations. Lubrication points such as bearings, bushings, and gear should always be lubricated to prevent any friction or binding that may affect the accuracy and efficiency of press operations. The grease gun should be checked for any blockages or leaks to ensure proper grease flow to all lubrication points.

Daily Calibration

Daily calibration is essential to maintain the accuracy and repeatability of servo press operations. Calibration involves checking the accuracy of the encoder scale, pressure sensor, and displacement sensor to ensure they are reading accurately. Additionally, the spring balance should be checked to ensure it is properly adjusted to provide accurate force control during press operations.

Cleaning and Maintenance

Regular cleaning and maintenance are essential to maintain the efficiency and longevity of servo presses. The press should be cleaned regularly to remove any foreign objects or debris that may have accumulated on its surface or within its components. Components such as the linkage system and bearings should be cleaned and inspected regularly for any debris buildup that may affect their function.

In conclusion, daily maintenance of servo presses involves visual inspection, checking the servo system, lubrication check, daily calibration, and cleaning and maintenance. Regularly performing these tasks will ensure the reliable performance and longevity of servo presses, leading to efficient and accurate manufacturing operations.

Post time: Oct-16-2023